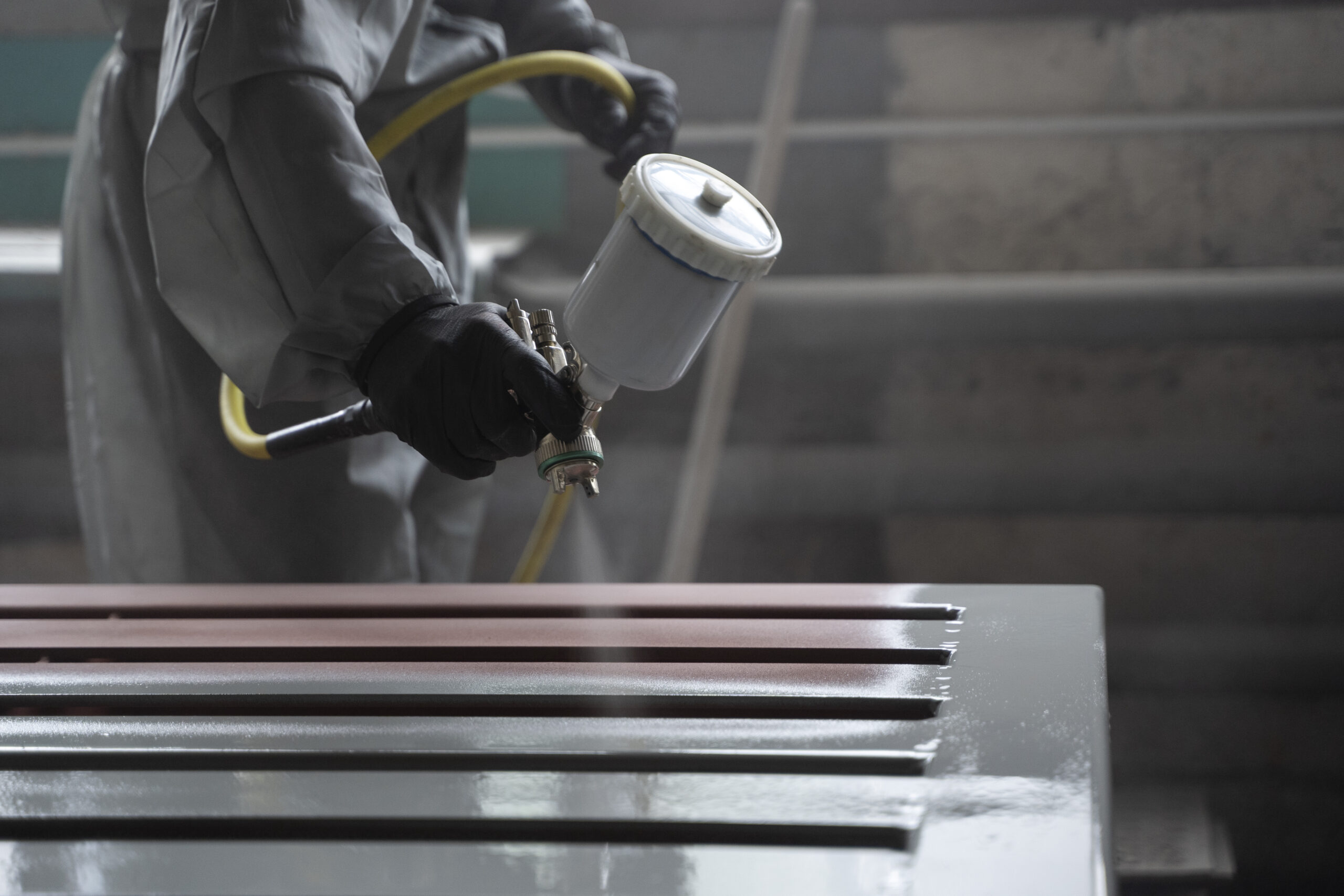

Efficiency is key when it comes to running a successful powder coating booth. From optimizing settings to incorporating the latest technology, small changes can lead to significant improvements in productivity and quality. Here are some lesser-known strategies to help you get the most out of your powder coating, paint spray booths, and blast booths.

Table of Contents

Optimize Powder Coating Gun Settings for Specific Parts

Fine-tuning your powder coating gun settings can make a world of difference in the quality of your finish. Each part you coat may require different settings to achieve optimal results. Adjusting factors such as voltage, air pressure, and powder flow rate ensures that the powder adheres evenly and reduces waste. Regularly check and adjust these settings based on the size, shape, and material of the parts being coated. This practice not only enhances the finish but also saves on powder usage over time.

Implement a Pre-Heating Stage to Enhance Powder Adhesion

Pre-heating parts before powder coating can significantly improve powder adhesion and reduce curing times. By heating the parts to a specific temperature, you create a surface that allows the powder to melt and stick more effectively. This step is especially useful for parts with complex shapes or those made from materials that are challenging to coat. A pre-heating stage can lead to a more uniform coating, reducing the need for touch-ups and increasing overall efficiency.

Use Anti-Static Devices to Reduce Powder Waste

Static electricity can cause powder to cling to unwanted areas, leading to waste and uneven coatings. Incorporating anti-static devices in your powder coating booth can mitigate this issue. Anti-static bars or ionizing air blowers neutralize static charges, ensuring that powder is applied only where it is needed. This not only reduces waste but also results in a cleaner working environment and higher-quality finishes. Implementing these devices is a simple yet effective way to enhance your booth’s efficiency.

Invest in Infrared Curing Technology for Faster Curing Times

Traditional curing methods can be time-consuming and energy-intensive. Infrared curing technology offers a faster and more energy-efficient alternative. Infrared ovens heat the powder-coated parts more quickly and evenly, reducing curing times significantly. This technology also consumes less energy compared to conventional ovens, leading to cost savings. By investing in infrared curing technology, you can increase your throughput and reduce downtime, making your powder coating booth more efficient.

Utilize Smart Scheduling Software to Minimize Downtime

Effective scheduling is crucial for maintaining a smooth workflow in your powder coating booth. Smart scheduling software can help you plan and manage your coating operations more efficiently. These tools allow you to schedule jobs based on factors such as part size, coating type, and curing times, ensuring that your booth operates at maximum capacity. By minimizing idle times and preventing bottlenecks, smart scheduling software helps you get the most out of your paint spray booths and blast booths, enhancing overall productivity.

Implement Proper Airflow Management to Prevent Powder Overspray

Airflow plays a critical role in the efficiency of a powder coating booth. Proper airflow management helps prevent powder overspray, which can lead to waste and poor coating quality. Ensure that your booth has adequate ventilation and that the airflow is directed appropriately. Using high-quality filters and maintaining them regularly can also improve airflow efficiency. By controlling overspray, you reduce powder waste, maintain a cleaner booth, and achieve better coating results, contributing to the overall efficiency of your operation.

Also Read : What is Branded Call Display and How Can It Benefit Your Business?

Conclusion

Maximizing the efficiency of your powder coating booth involves a combination of optimizing settings, utilizing advanced technologies, and maintaining proper airflow and scheduling. By implementing these lesser-known strategies, you can enhance the performance of your powder coating booths, paint spray booths, and blast booths, leading to higher productivity, reduced waste, and superior coating quality.