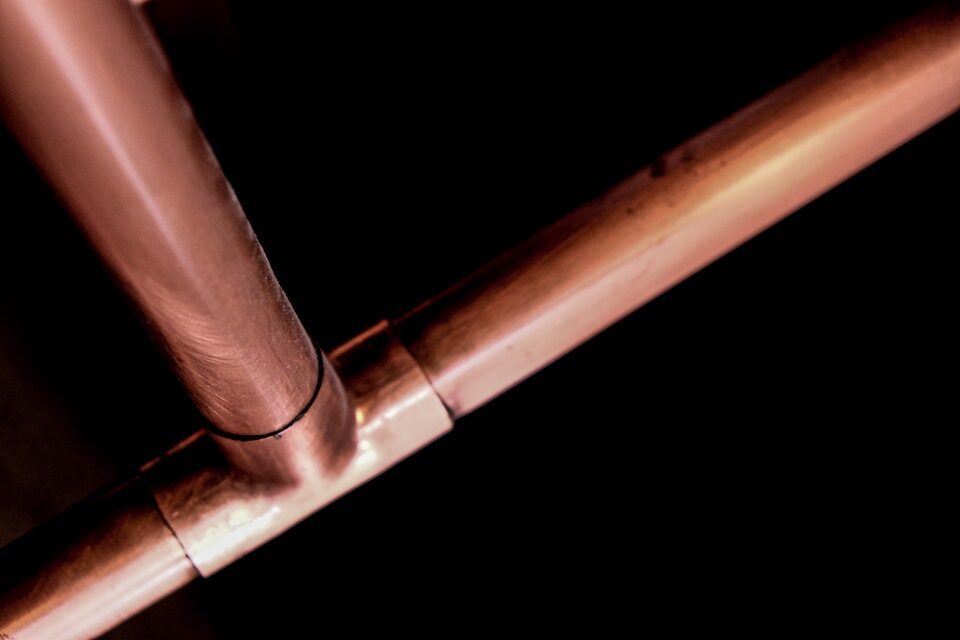

Tube clamps are the components that connect individual lengths of tubing to other sections of tubing, pipe, hose, or other components. Straight sections are the most common component of system configurations, and these sections are often joined together via fittings, specifically constructed connections, or joints.

Table of Contents

Tube Clamps Basics

Body, front ferrule, back ferrule, and nut are the components that make up these tube fittings. When a typical two ferrule tube clamp is “made up” or tightened, the front ferrule is intended to be driven forward into the body of the fitting. The process seal between the body and the tubing is created as a result of this step. There are many types of tube clamps direct that you can use as per your need.

The back or rear ferrule is smaller than the front or middle ferrule and is designed to “bite” the tubing to provide stability to the entire connection. A single ferrule in a single-ferrule clamp performs the function of both the front and rear ferrules in a 2-ferrule fitting. This is because the design of single-ferrule fittings is a little different.

When to Use Tube Fittings?

A pipe is used for the construction of the majority of the main fluid lines in any processing facility. Using only piping components to attach any mechanical or electrical monitoring instrument to the process can be expensive and lead to several leak pathways. Tubing can be used for this purpose.

A technician can access several benefits that are not available when using only plumbing components. Tubing can be bent to locate equipment in precise locations or allow for connection to a tap point that may be difficult to access. Tubing may be trimmed to the exact lengths necessary, and using a tube clamp can be conveniently linked to other pipework or equipment. Both of these uses can be accomplished by bending the tube.

Benefits of Using Tube Fittings

There are various types of tube clamps here. Why is it that people prefer steel fittings? The answer lies in the benefits of using these fittings. These include:

- They are durable

- They have a high-temperature tolerance

- They are malleable

- They have high resistance to corrosion

- They are versatile

Types of Tubular Clamps

The fact that such a wide variety of brass fittings are available to choose from contributes to the adaptability of these components. The following are some of the most frequent ones:

- Pipe adaptors: used to change the connection type at the end of a pipe

- Pipe couplings: used to connect similar pipes

- Pipe nipples: used to connect two fittings

- Pipe tees: shaped like a “T,” used when more than one branch is required for a water supply

- Pipe unions: used similarly to couplings

- Pipe plugs: used to close pipes

- Pipe elbows: used to divert the direction of water flow between pipes

- Pipe wyes: shape like a “Y,” used to join pipes at a 45-degree angle

Also read: What To Do When Your Water Line Is Broken

Final Takeaway

Tube clamps made of steel are an excellent choice for various plumbing applications, including residential and industrial ones. Because of their longevity, dependability, and quality, tube clamps are a worthwhile investment. Even if they tend to cost a bit more, the price difference between them and the other choices is not overly dramatic.